|

NonStopTuning’s commitment to research & development includes putting products to the test in professional motorsports series and competitions. NST has campaigned drivers in Formula Drift, holds records for most podium finishes during back to back Xtreme Drift Circuit National Championships, and holds multiple FD Pro Am Lone Star Drift Championships. Check out the latest Alex Lichliter promo video to see a number of our products in action during the 2023 Formula Drift season! NonStopTuning Hydraulic Handbrakes: CNC machined and anodized for extra strength and durability Pass Through Master (single caliper) included with each handbrake Dual Master (dual caliper) can be added as an upgrade Three colors: Silver, Black, Neochrome NonStopTuning Pulley kits: 70-75% weight reduction vs OEM Dyno Proven Horsepower & Torque Better Throttle Response & Fuel Economy Ongoing Research & Development: 50+ Engines offered Custom Pulleys Available As Special Order Items Five colors: Red, Black, Purple, Blue, Gold NonStopTuning Forged Steel Lug Nuts: Full engagement, open top to accommodate long race studs Quality Forged Steel for strength and durability Compact size to fit small diameter wheel holes Backed by a full One Year warranty NonStopTuning Steering Wheel Kits: Carbon Fiber, Classic Leather, Alcantara Steering Wheels Short Hubs & Splined Quick Releases for most Makes & Models Seven Colors: Black, Red, Gold, Blue, Titanium, Purple, Neochrome NST - NonStopTuning

www.NonStopTuning.com

0 Comments

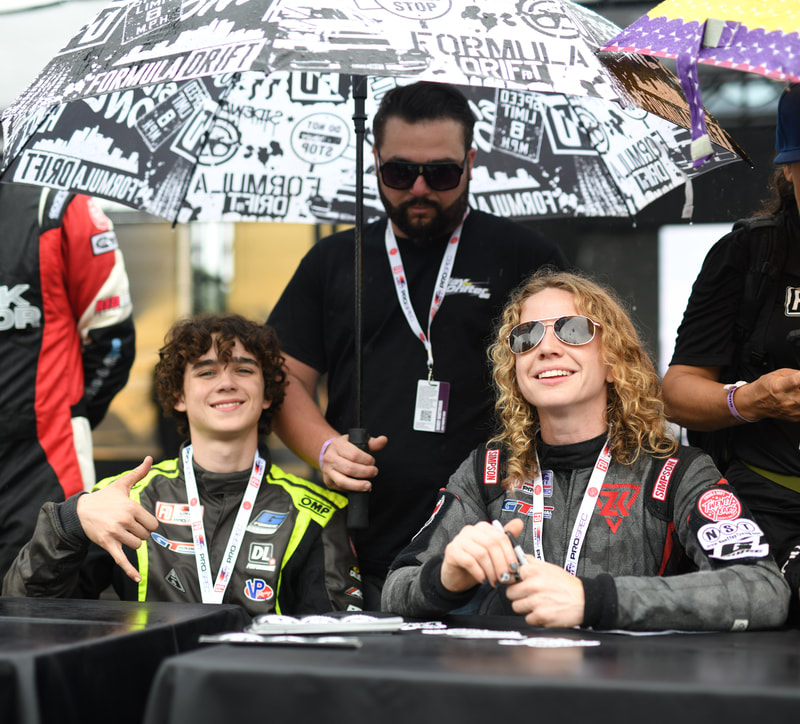

Zandara Kennedy recaps her first trip to Atlanta for Round One of the 2023 Formula Drift ProSpec Series. Detailing her team's adventures in the practice sessions, dealing with overnight repairs, and going through her first FD qualifying session. NST - NonStopTuning www.NonStopTuning.com Alex Lichlither recaps his first trip to Atlanta for Round One of the 2023 Formula Drift ProSpec Series. From the early test and tune process, through practice, and qualifying. NST - NonStopTuning www.NonStopTuning.com NonStopTuning is proud to announce the latest signing to our professional drift team, Zandara Kennedy! Zandara "Zee" Kennedy is a professional stunt performer and stunt driver from Vancouver, Canada - if you watch movies or TV, you've most likely seen her in action, maybe even on fire. She loves to drive anything with a motor, from scooters to tractor trailers, and is happiest when driving them sideways. Her desire to perfect her craft brought her attention to drifting, where she worked with coach and FD Veteran Taka Aono (former NST driver) to improve her skills and eventually earned her FD license in 2021 - she will be competing in the ProSpec category in the 2023 season of Formula Drift. When not on set or under her cars, she loves to share her passion for drifting with as many people as possible, especially through ride-alongs. She works with the Della Penna Next Gen foundation, Racing Pride and Athlete Ally to promote diversity of all kinds in motorsport. For 2023, Zandara will be campaigning a new chassis - an 800HP 2JZ swapped Nissan 240SX freshly kitted out with NST goodies. "I'm thrilled to be working with NST, a company with such an extensive investment and history in North American drifting, and a clear passion for providing their customers with the best possible products that will help them get the most out of their vehicles. I'm very excited to see what we can achieve together this season!" We look forward to working with Zandara and her crew, providing products and support as they pursue their rookie year in Formula Drift. We kicked off the Formula Drift season with a bang (a couple of them actually)! Long Beach is always the toughest track of the year as it is the first stop after a long off season and one of the most intimidating. The track surface is very unpredictable and the slightest error or correction can send you into dangerous territory. But what a way to shake off the nerves and get pumped for the season! We had a very successful start to the year. Join Alex Lichliter on his journey through the final round of the Formula Drift PROSPEC series, at the Utah Motorsports Campus in Salt Lake City. From early morning Driver's meetings, to varying track temps, all the way through qualifying and competition.

NST - NonStopTuning www.NonStopTuning.com Formula Drift driver Carlos Arrieta shares his mid season recap, showing off his Toyota JZ powered SC300. Check out those NST parts on the car! We'll continue to develop more products for this engine and chassis combination as the season continues. NST - NonStopTuning www.NonStopTuning.com Formula Drift driver Alex Lichliter took a few minutes to shoot a little promo video with his V8 powered 86, and we think it's pretty cool! We'll be developing more parts for the LS engine, and the 86 chassis, as the in-season development of this car continues. NST - NonStopTuning www.NonStopTuning.com NonStopTuning is proud to announce new sponsorship opportunities for three new drivers for the 2022 season. Three spots are available and expected to be filled by the spring of 2022, for as many as three Formula Drift PROSPEC drivers. Prospective drivers are encouraged to apply by March 11, 2022. Who Is Eligible? Any driver in the Formula Drift PROSPEC series Basic Requirements: Formula Drift PRO/PROSPEC licensed driver Formula Drift PRO/PROSPEC vehicle meeting all rule-book requirements Driver/Team must have the ability to provide media/video updates Driver/Team must have established pit crew staff and support team Registration Deadline: Interested drivers must email driver packets to [email protected] by March 11, 2022. Thank you all for your interest and support, best of luck with all your projects! In no particular order, some of our favorite photos from our first fifteen years as a company! NST - NonStopTuning www.NonStopTuning.com |

AuthorNST - NonStopTuning Archives

July 2024

Categories

All

|

www.NonStopTuning.com has had visitors from over 180 countries and has served more than 50,000 customers since 2005

RSS Feed

RSS Feed