|

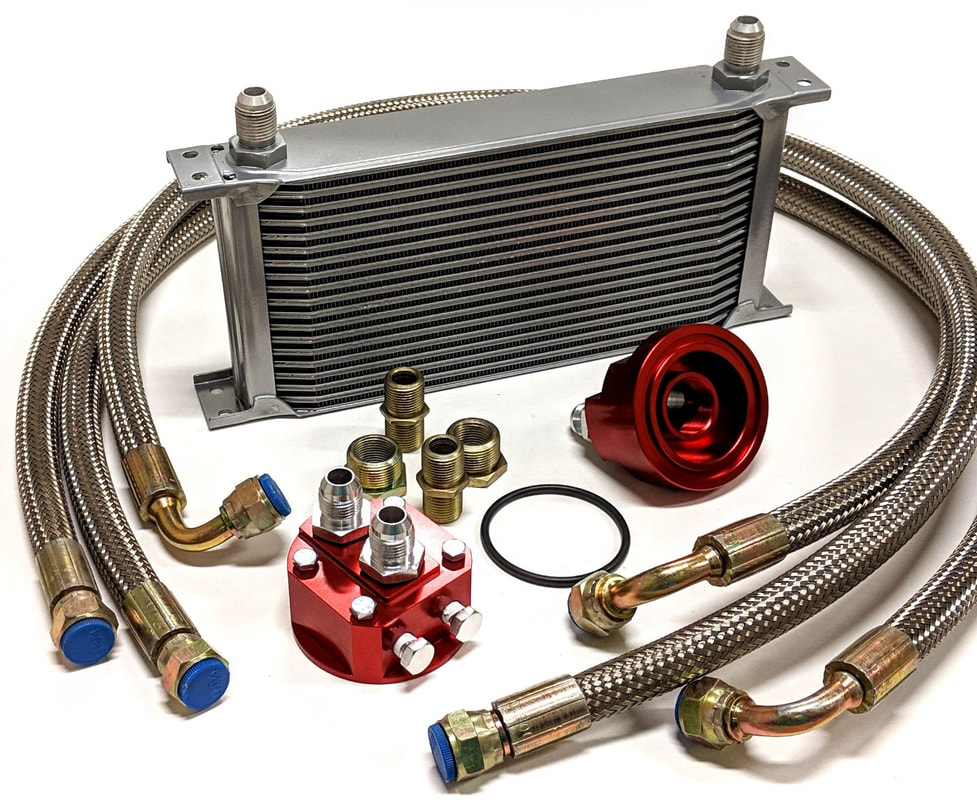

We get this question a lot, "I want an oil cooler kit, but they seem complicated. Are they hard to install?" No, they are not very complicated, and you should be able to handle your own install if you have a little experience with wrenching on your car. We even decided to offer up a simple video to help you get started. Follow along as our friend Brad, aka OKBRZ, walks you through the install process on his Subaru BRZ. Ready for your own Oil Cooler Kit? We offer both standard sandwich plate oil cooler kits and remote oil cooler kits, at very reasonable prices, and ship them to any destination free of charge. Below are just a few examples... Have questions? Need a custom cooler in a different size? Just email us and we'll do our best to help you with your project! NST - NonStopTuning www.NonStopTuning.com

0 Comments

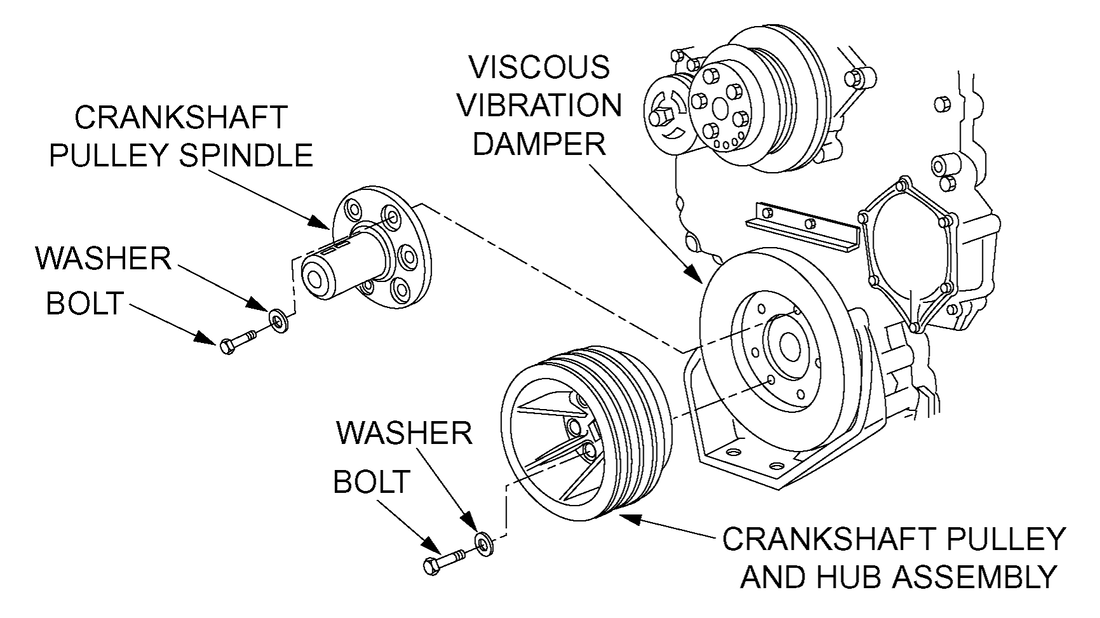

ON THE TOPIC OF LIGHTWEIGHT CRANK PULLEY VIBRATIONS, HARMONICS, AND SAFETYQ. Do lightweight aluminum crank pulleys lead to premature engine failure? Most American V8 engines of the muscle car era (50s-60s) were externally balanced. An external (harmonic/vibration) balancer was attached to the outside of the engine on the crank snout. The crank pulley in such engines was a separate piece attached to this balancer and the removal of this balancer was a bad idea. External balancers were most often used on large displacement V8 engines and the majority of today’s internet forums and social media discussions regarding harmonics stem from this principle. Modern (1980s and up) Honda, Toyota, Nissan, or other Japanese engines are NOT equipped with external balancers. These engines are internally balanced and this process has improved even further since the 90s. So the topic of a BALANCER does not apply here. The crank pulley found on many modern engines is often called a harmonic damper. The damper is a thin rubber band, approximately (1/8 inch) 2mm, built into the crank pulley. This rubber is used to absorb something called NVH, noise/vibration/harshness. Suffice it to say, this rubber is actually not very good at performing its intended purpose after as little as a few thousand miles. What happens to rubber after exposure to weather conditions such as humidity, rain, snow? It often becomes brittle, hard, and crunchy. Can something with such properties absorb vibrations? Not very well. NST customers often report smoother running engines after installing NST pulleys, especially at idle. How is this possible if the rubber is such a vital piece? As it turns out, the rubber is not as important as it's cracked up to be. On a well maintained engine with bolt-ons or low amounts of boost like what most owners probably run, a lightweight aluminum crank pulley will not have any life threatening consequences. The engineering reasons are that most modern engines have a short (increasingly strong) crankshaft operating under 8,000 RPM. The dangerous second harmonic that can cause damage occurs at an RPM that this sort of engine will never see, in the area around 10,000 RPM. Even the OEM damper is not tuned for attenuation above 10,000 RPM, so the argument is somewhat of a moot point. The great majority of our customers do not fall into the latter category. How many 500+ HP, 10,000+ RPM engines do we have on the street? Not many. Q. Does NST have cars/customers in professional motorsports using its products? NST has campaigned several pro cars in the professional drift series, Fromula Drift. Our cars have also competed in D1 GP USA, Xtreme Drift Circuit, and the NOPI Drift series. A large number of Honda, Toyota, and Nissan tuners use underdrive crank pulleys in road racing series like NASA or SCCA. Road racing is often more punishing on an engine than other motorsports. The engine is subjected to run times lasting apx 30 minutes with the engine often in the upper ranges of its RPM limit. One race weekend is the equivalent of hundreds of quarter mile passes. These tuners would not use NST pulleys if they were not reliable. NST sponsored the first ever wheel to wheel Scion tC NASA Road Race car. The same car was very competitive in the Grand Am series and had factory backing from Toyota, Scion, and TRD. This car used pulleys from NST with great results since day one. Furthermore, NST products are also used in autocross, time attack, hill climb, and drag racing series. SUMMARY ON VIBRATIONS, HARMONICS, SAFETY Older American V8 engines are externally balanced and require pulleys designed specifically for those applications, or damage to the engine could result. You will not find solid aluminum NST pulleys on our website for such engines. Modern Honda, Toyota, Nissan, and other similar engines are NOT equipped with external balancers. These engines are internally balanced and this process has improved even further since the 1990s. So the topic of a BALANCER does not apply here. High RPM engines, when modified well beyond the simple bolt-on stages, may have issues with solid aluminum pulleys. Such engines reach critical harmonics above 10,000 RPM, a range in which the dangerous wave of harmonics can come into play. For such RACE engines, OEM dampers are also not sufficient. The overwhelming majority of our customers’ engines do not fall into the above categories, and as a result, will actually benefit from the lightweight pulleys NST offers. These engines will not suffer damages in street and/or track use when NST products are installed properly. We're confident every “expert” preaching otherwise has little personal, practical, real world experience with the subject; as it applies in your case. NST - NonStopTuning

www.NonStopTuning.com |

AuthorNST - NonStopTuning Archives

July 2024

Categories

All

|

www.NonStopTuning.com has had visitors from over 180 countries and has served more than 50,000 customers since 2005

RSS Feed

RSS Feed